Welcome to the premier supplier of cutting-edge Metal Injection Molding (MIM) solutions, Murlidhar Metalline Industries. Our expertise with MIM technology promises the creation of intricate, high-quality metal components that satisfy the exacting specifications of several industries.

Metal Injection Molding (MIM) is a modern manufacturing method that produces complex and complicated metal parts with high precision and cost-effectiveness. MIM is perfect for industries like electronics, automotive, medical, and aerospace that need small, intricate components because it combines the strength of metal with the flexibility of plastic injection molding. To create solid metal pieces with great mechanical strength, a metal powder-binder feedstock is created, injected into a mold, debound, and then sintered. Delivering top-notch MIM solutions with accuracy, consistency, and dependability for even the most demanding applications is where Murlidhar Metalline Industries shines.

We at Murlidhar Metalline Industries are dedicated to providing excellence via clarity and innovation. Our top-notch metal injection molding services, which serve a variety of applications, are made possible by our state-of-the-art facilities and knowledgeable team.

Metal Injection Molding (MIM) is a manufacturing technique that molds metal objects by injecting a metal-rich powder mix into a mould. It makes it possible to produce extremely intricate shapes in metal with the same level of accuracy usually found in plastic injection molding. When working with small, complex pieces that are difficult for typical metalworking processes to produce economically, MIM is especially helpful.

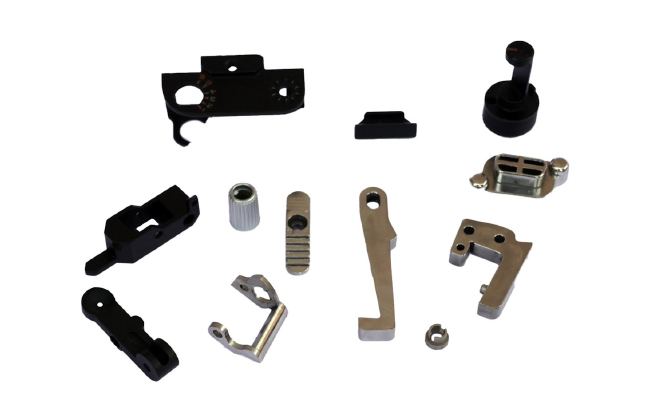

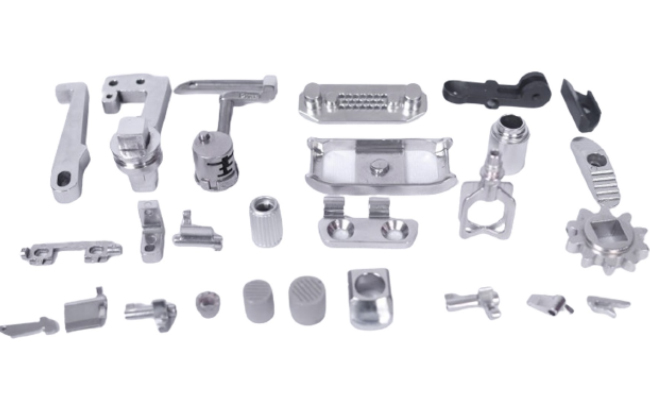

Metal injection molded parts have transformed the manufacturing industry by enabling the creation of complex metal components with high precision and consistency. The flexibility of plastic injection molding and the strength of metal are combined in the Metal Injection Molding (MIM) process, which makes it perfect for small, intricate pieces that are costly or challenging to make with conventional techniques like casting or machining.

Murlidhar Metalline Industries, a leading company in the field, is always expanding the boundaries of metal injection molded components. In order to improve our procedures and give our clients the most advanced solutions possible, we make investments in modern technology, research, and development.

| Category | Criteria |

|---|---|

| Component Weight | 0.1 - 100 gm |

| Dimensional Range | 1-100 mm |

| Wall Thickness | 0.025- 15 mm |

| Tolerance | 0.2-1.0% |

| Production Quantity | >1000 |

| Surface Finish | 0.3 microns |

| Percent Theoretical Strength | 95-100% |

| Percent Theoretical Density | 95-100% |